IoT In Manufacturing

Did you know?

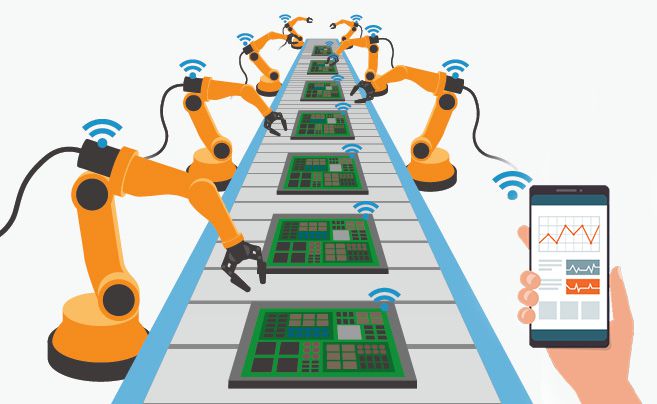

Smart manufacturing is the use of IoT devices to improve the efficiency and productivity of manufacturing operations. IoT is profitable in the fields where both faster developments, as well as the quality of products, are the critical factors for a higher Return on Investment. IoT can facilitate the production flow in a manufacturing plant, as IoT devices automatically monitor development cycles, and manage warehouses as well as inventories. We’re helping manufacturers like you to exploit these new opportunities, and overcome growing challenges. With our support, organizations can use connected manufacturing to deliver new products-as-a-service, including support for customization.

How IoT in manufacturing work?

To make better-informed decisions and optimize production, IoT system allows factory managers to automatically collect and analyze data. The data is collected from sensors and machines which is communicated to the Cloud by IoT connectivity solutions deployed in the factory. Then, the collected data is analyzed and combined with contextual information and shared with authorized stakeholders. After the data is analyzed, enables this flow of data to remotely monitor and manage processes and change production plans quickly, in real time when needed. Therefore, with IoT, you can Achieve operational excellence across your processes, maximize production yield while reducing waste, and monitor asset integrity to avoid critical and costly downtime.

How is IoT used in manufacturing?

Digital/connected factory

- Machinery can transmit operational information to the partners like original equipment manufacturers and to field engineers.

- Enable operation managers and factory heads to remotely manage the factory units

Facility management

- IoT Sensors can actively monitor machines and send an alert when the equipment deviates from its prescribed parameters.

- Ensuring the prescribed working environment for machinery, manufacturers can conserve energy, reduce costs, eliminate machine downtime and increase operational efficiency.

Production flow monitoring

- Enable the monitoring of production lines starting from the refining process down to the packaging of final products.

- Provides scope to recommend adjustments in operations for better management of operational cost.

Inventory management

- The inventory is tracked and traced globally on a line-item level and the users are notified of any significant deviations from the plans.

- Managers are provided with realistic estimates of the available material, work in progress and estimated the arrival time of new materials.

Monitoring safety

- Workers receive RFID tags that gather data on their location and wearable sensors collecting data about their heart rate, skin temperature, galvanic skin response, and other parameters.

Quality control

- IoT sensors collect aggregate product data and other third-party syndicated data from various stages of a product cycle.

- IoT device can provide data about the customer sentiments on using the product and analyzed to identify and correct quality issues.

Packaging Optimization

- IoT sensors in products and/or packaging, manufacturers can gain insights into the usage patterns and handling of product from multiple customers.

- trace product deterioration during transit and impact of weather, road and other environment variables on the product.

Logistics and Supply Chain Optimization

- Provide access to real-time supply chain information by tracking materials, equipment, and products as they move through the supply chain.

dpstar is the top supplier of IoT System with 30+ years of experience in Malaysia. Our expertise lies in electrical, instrumentations, controls, and automation. We have experienced engineers to assist you to find the perfect solution for your applications. For more information, please visit our website at www.dpstar.com.my or send your inquiry to info@dpstar.com.my.

/image%2F1596981%2F20160816%2Fob_92a19e_dpstar-logo.png)

/image%2F1596981%2F20190528%2Fob_bb5634_flow-switch-dpstargroup.png)

/image%2F1596981%2F20190527%2Fob_f18543_iot-in-manufacturing-dpstargroup.jpg)

/image%2F1596981%2F20190524%2Fob_24f6f7_iot-in-transportantion-dpstargroup.png)